The Impact of Quality Control Processes on Thermal Camera Lifespan

2025/12/05The longevity and reliability of thermal imaging cameras are crucial for businesses that depend on this technology for various applications. The quality control processes employed by thermal imaging camera manufacturers significantly influence product lifespan and performance. This article examines how stringent quality control measures contribute to the durability and effectiveness of thermal cameras, particularly in custom thermal solutions.

Rigorous Testing Protocols

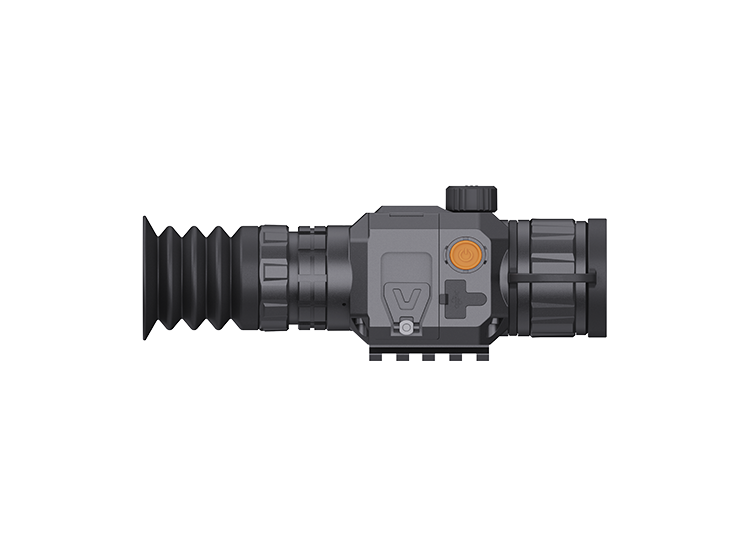

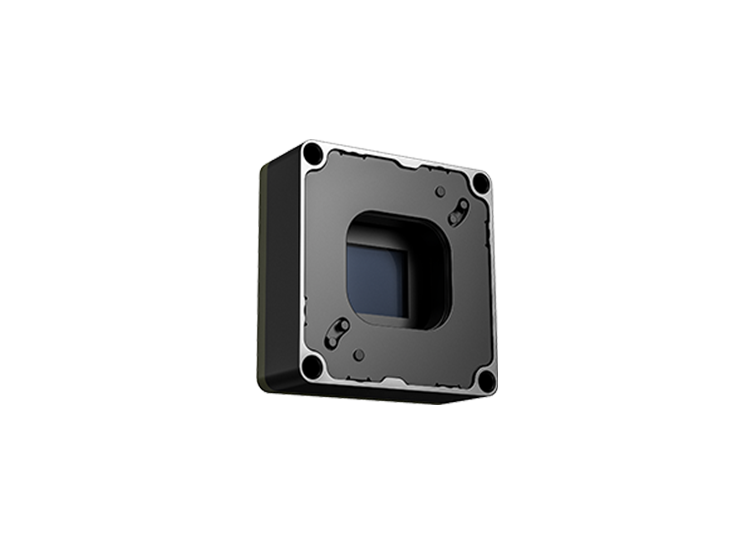

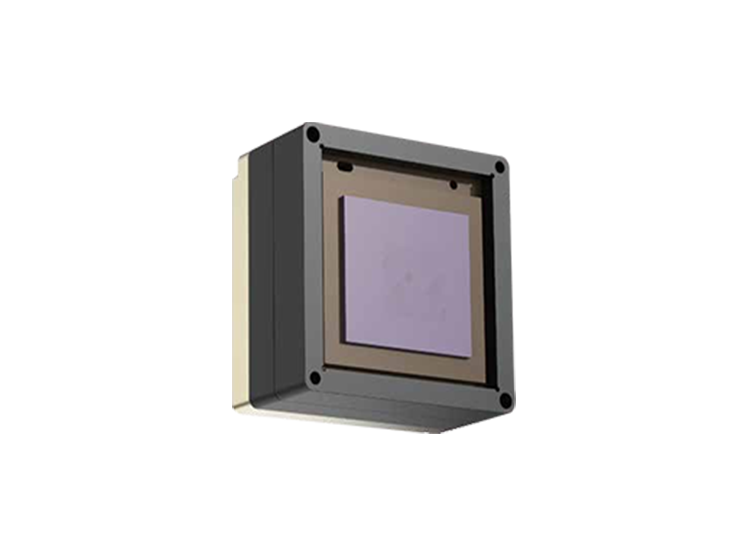

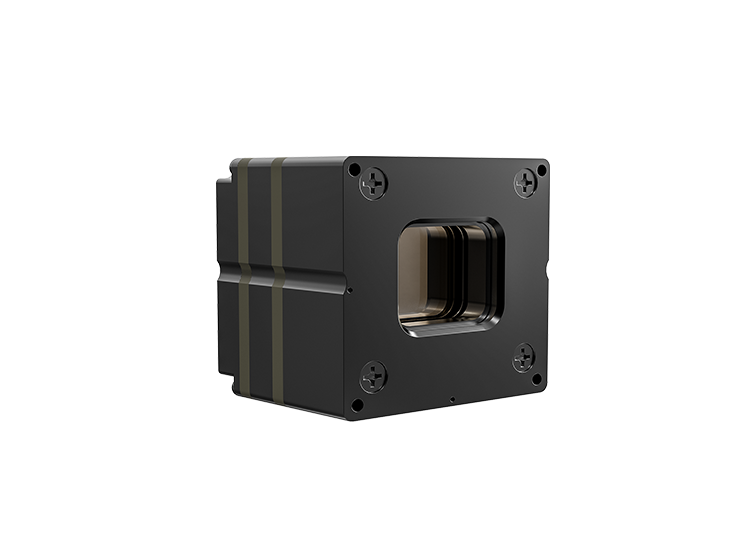

Quality control begins with rigorous testing protocols that thermal imaging camera manufacturers implement throughout the production process. These protocols ensure that each component meets high standards before assembly. For example, the Fireye series uncooled thermal modules utilize highly reliable infrared detectors that undergo extensive testing for shock and impact resistance. By identifying and addressing potential weaknesses early in the manufacturing process, companies can enhance the overall durability of their products, significantly extending the lifespan of the thermal cameras.

Superior Material Selection

Another critical aspect of quality control is the selection of materials used in manufacturing thermal cameras. Manufacturers that prioritize quality often choose high-grade materials that can withstand various environmental conditions. This choice is vital for ensuring that the thermal imaging camera performs optimally over time. For instance, the Fireye series incorporates independently developed core components, including lenses and detectors, designed for technical security and autonomous reliability. The use of superior materials not only enhances performance but also reduces the likelihood of premature failure, contributing to a longer product lifespan.

Continuous Improvement and Feedback Loops

Effective quality control processes involve continuous improvement and feedback loops. Thermal imaging camera manufacturers that actively seek feedback from users can identify areas for enhancement in their custom thermal solutions. This feedback is essential for addressing user concerns and adapting to emerging technologies. Regular updates and improvements based on customer experiences can lead to enhanced product features and increased durability. Manufacturers who invest in this iterative process are more likely to produce thermal cameras that remain functional and reliable over extended periods.

Elevating Standards in Thermal Imaging Solutions

The quality control processes of thermal imaging camera manufacturers play a pivotal role in determining product lifespan and performance. Rigorous testing, superior material selection, and a commitment to continuous improvement are key factors that contribute to the durability of thermal cameras.

At IRVOTEX, we take pride in our quality control measures, ensuring that our Fireye series uncooled thermal modules meet the highest standards of reliability and performance. Our commitment to integrating hardware and software seamlessly allows us to deliver custom thermal solutions that cater to diverse application scenarios. With our focus on quality, we strive to provide our customers with thermal imaging cameras that not only meet their immediate needs but also stand the test of time. Let us help you enhance your operations with our advanced thermal imaging technology.

+86 (028) 8535 5966

+86 (028) 8535 5966 +86 17323184180

+86 17323184180 irvotex@votinfrared.com

irvotex@votinfrared.com