Ensuring Consistency in Mass Production of Thermal Imaging Sensors

2025/12/03The demand for thermal imaging technology has surged across various industries, including security, automotive, and medical applications. As the market grows, thermal imaging sensor manufacturers face the challenge of maintaining consistency in mass production while meeting diverse customer needs. Achieving this balance is crucial for ensuring product reliability and performance.

Standardization of Manufacturing Processes

One of the primary methods thermal imaging sensor manufacturers employ to ensure consistency in mass production is the standardization of manufacturing processes. By implementing strict protocols and guidelines, manufacturers can minimize variations in production. This includes defining precise specifications for materials, components, and assembly methods.

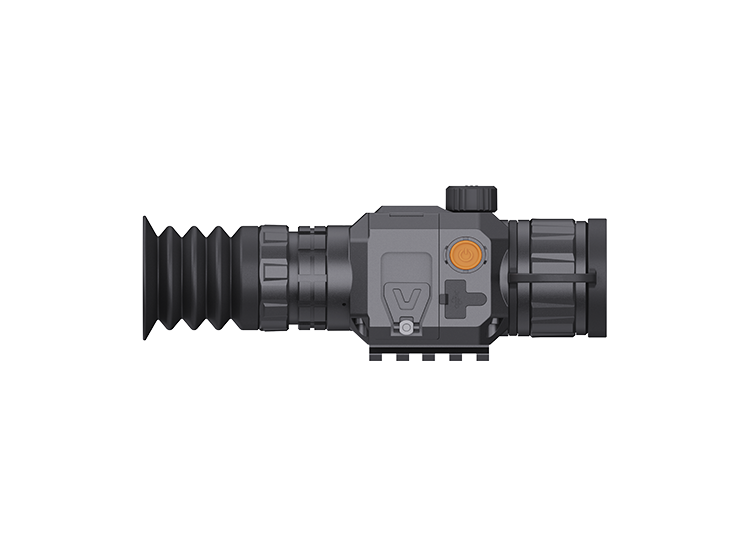

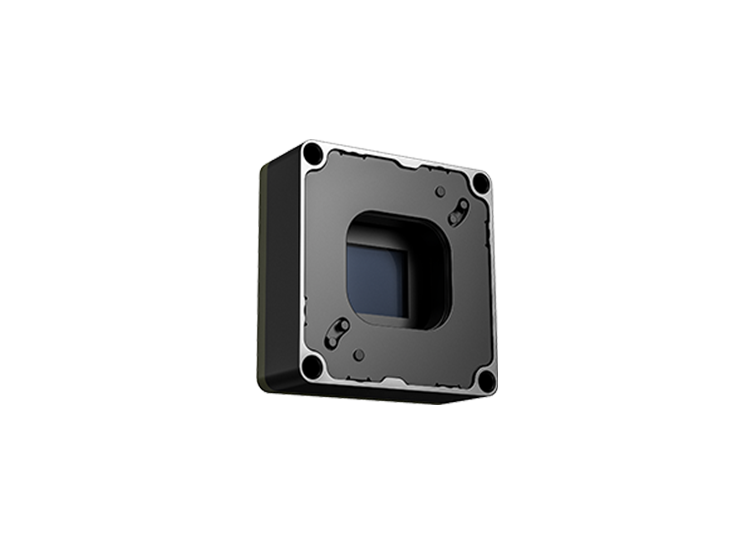

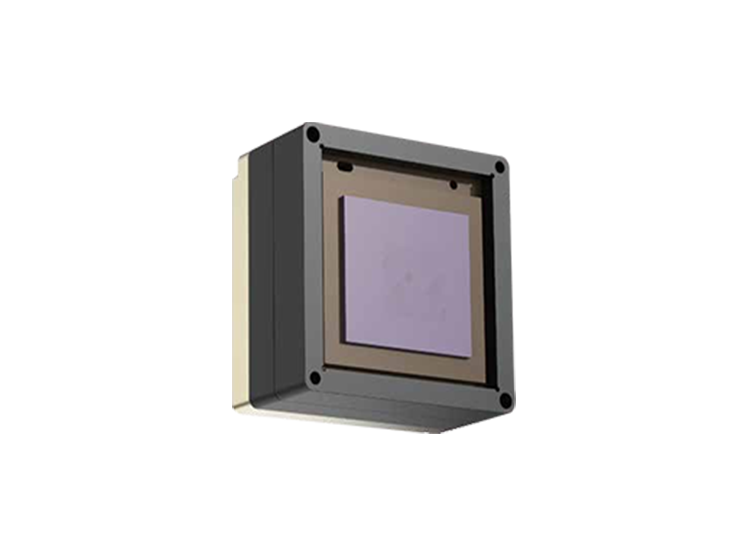

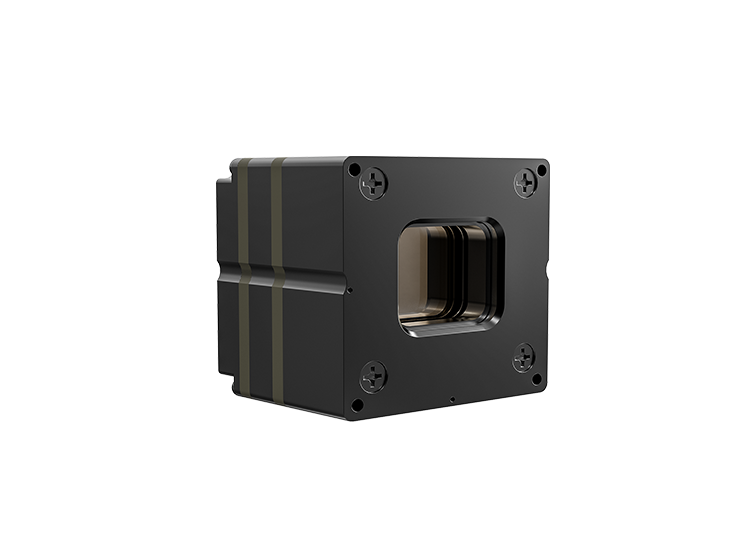

Standardized processes also facilitate quality control at every stage of production. Regular inspections and testing are conducted to ensure that each thermal imaging sensor meets established performance criteria. For instance, IRVOTEX’s Spiritpupil Series uncooled thermal module exemplifies this approach, with comprehensive quality assurance measures in place to guarantee that each unit performs reliably across various applications.

Advanced Technology and Automation

The use of advanced technology and automation plays a vital role in ensuring consistency during mass production. Thermal imaging sensor manufacturers increasingly rely on automated machinery and robotics to perform repetitive tasks with high precision. This not only reduces human error but also increases production speed, allowing manufacturers to meet growing demand without sacrificing quality.

Moreover, automated systems can be programmed to monitor product specifications in real time, immediately flagging any deviations from established norms. By integrating advanced manufacturing technologies, thermal imaging sensor manufacturers can produce custom thermal solutions that are both consistent and tailored to specific customer requirements.

Customization Without Compromising Quality

While consistency is paramount, thermal imaging sensor manufacturers must also offer customization options to meet diverse client needs. Balancing mass production with customization is a complex task; however, manufacturers can achieve this by employing modular designs and interchangeable components.

For example, the Spiritpupil Series includes customizable interfaces and a variety of interchangeable infrared lenses. This design allows customers to adapt the thermal imaging sensor to various applications without compromising the integrity or performance of the product. By maintaining a flexible approach to customization, thermal imaging sensor manufacturers ensure that they can deliver high-quality, reliable solutions that meet specific market demands.

Partnering with IRVOTEX for Consistent Quality

The challenge of ensuring consistency in mass production of thermal imaging sensors is met through standardization, advanced technology, and customization. At IRVOTEX, we are dedicated to producing high-performance custom thermal solutions that meet the evolving needs of our clients. Our Spiritpupil Series uncooled thermal module exemplifies our commitment to quality and innovation, offering reliable performance.

+86 (028) 8535 5966

+86 (028) 8535 5966 +86 17323184180

+86 17323184180 irvotex@votinfrared.com

irvotex@votinfrared.com